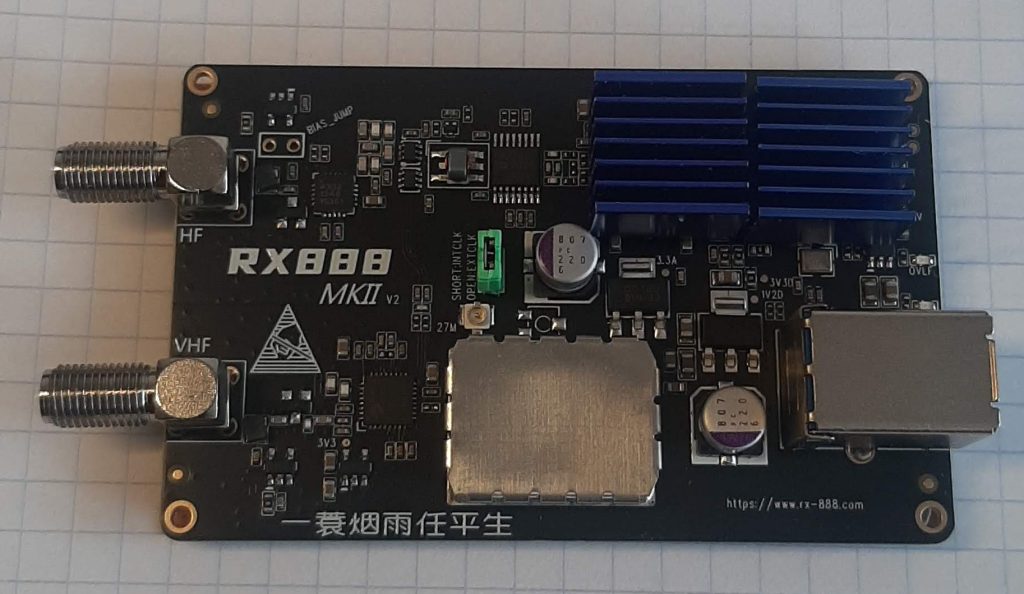

TheRX888mk2 is an outstanding SDR receiver that impresses with its capabilities.

This device is a true gem in its category, featuring a fantastic 16-bit ADC that provides incredible sensitivity and signal dynamics. Thanks to the high-speed USB3 interface, data transfer is instantaneous, while the wide frequency range from 0 to 2 GHz opens the door to exploring countless radio bands.

However, its biggest problem is thermal management. The converter gets significantly hot, as other users have already noted, and other components, like the USB3 communication chip, are not cool either. With a little effort, it is possible to significantly improve the thermal parameters and protect the device from overheating.

My idea (which works very well) involves two main modifications:

1. External Heatsinks

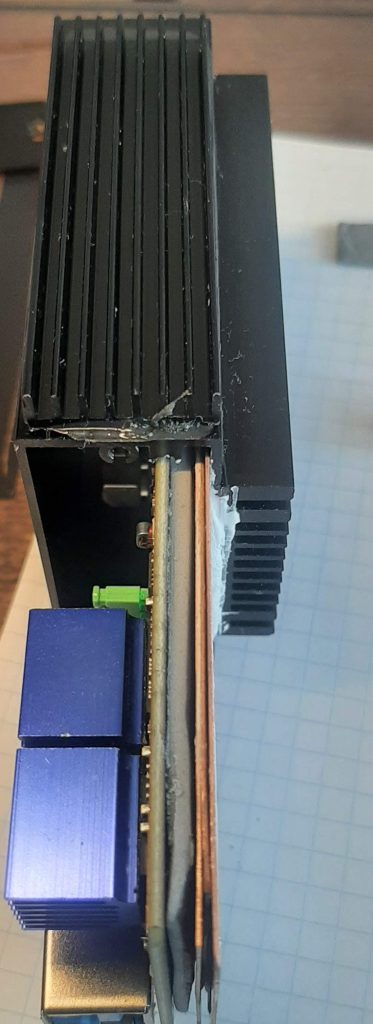

Re-gluing the external heatsinks using a black epoxy resin-based glue (such as those used for car repairs, foto above). First, you need to remove the paper-glued external heatsinks. They should peel off quite well after light heating. The surface should be wiped with spirit or acetone, and then the heatsinks should be re-attached, pressing them firmly while the glue sets.

2. Internal Thermal Management

The second important modification is to apply a 3mm-thick silicone thermal pad across the entire bottom surface of the PCB. You can find options for this on platforms like AliExpress, such as the Upsiren 24W/MK 21/18/16W GPU CPU thermal pad. It is best to choose a pad with the highest possible thermal conductivity.

To effectively transfer heat to the device’s casing, you should cut three copper plates (aluminum is also an option). These plates should be coated with a silicone thermal paste (the cheapest kind will do). The inside of the casing should also be coated with this paste to ensure optimal thermal contact between the thermal pad, the plates, and the casing. Then, simply slide the three plates between the PCB and the case. This approach eliminates the difficulty of squeezing in a thick 5mm pad and significantly improves thermal conductivity, as copper is highly effective.

Technical Details

- The copper plates should be slightly narrower than the PCB to avoid interfering with the rails that hold the board.

- The length can be exactly the same as the board’s length, but it is not critical.

- The thickness of the plates should be 0.5mm.

Another step in the upgrade is to replace the original converter heatsink (which is comically small and attached with paper) with a larger one using a proper adhesive. I also added a heatsink to the USB3 chip. After assembly and cleaning off the thermal paste, the unit works perfectly. The case becomes warm shortly after powering on, which indicates excellent heat dissipation.

However, in retrospect, I believe the device still generates a significant amount of heat. During prolonged use, the thermally-modified case becomes simply hot. It is frightening to think what happens inside without such modifications. Nevertheless, even a small fan can solve this issue. I am confident that a receiver modified in this way can operate for years without the risk of overheating.